TLS Screed

Super lightweight aggregate for the preparation of lightweight insulation screed

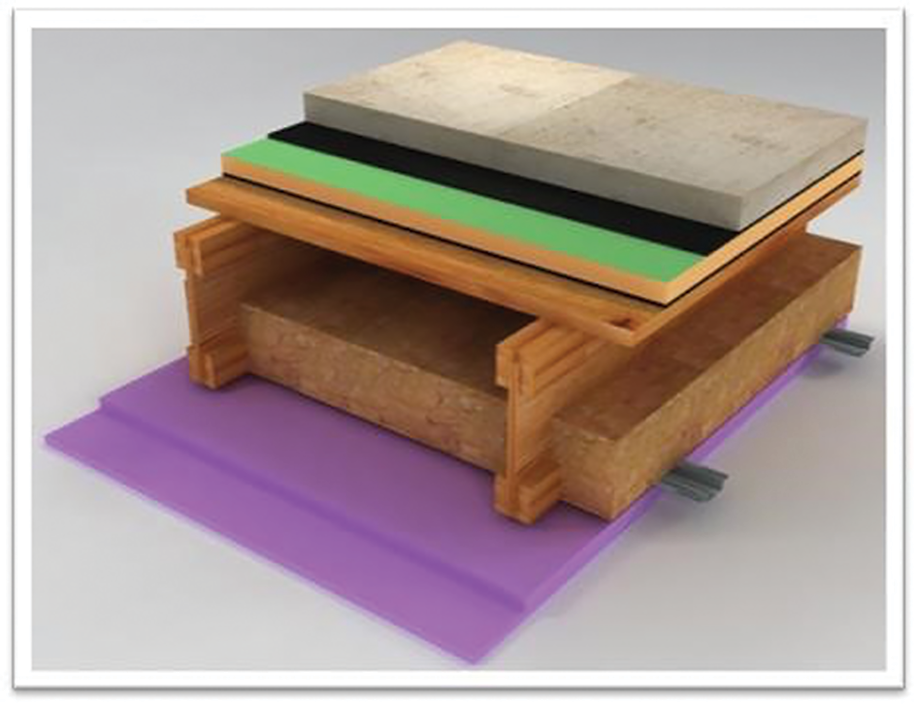

Our innovative aggregate goes through a range of specific processes that have allowed it to become a market leader for use in thermal and lightweight screeds. This exciting new product offers architects, developers, and builders a great alternative to traditional methods of insulating both ground and upper floors.

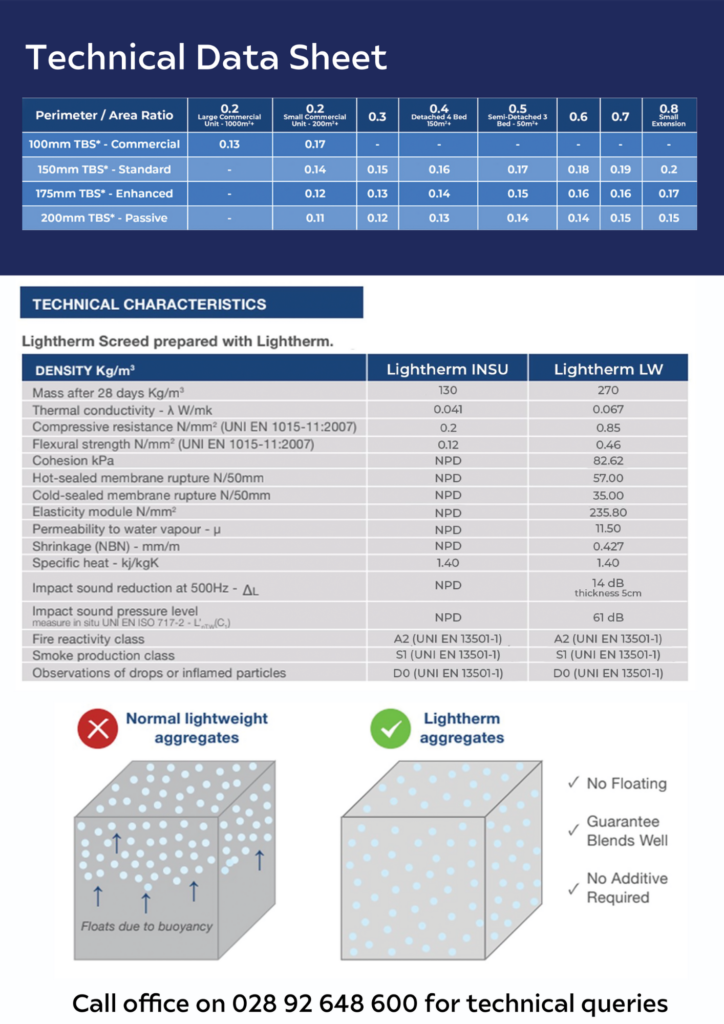

When mixed at a specific ratio with cement and water it becomes a lightweight thermal bead screed, with exceptional thermal and acoustic properties and has thermal conductivity values as low as 0.041 W/m.K. TLS offers solutions to reduction in loading with huge advantages in reduction of Dead Loads on intermediate floors with a density of 270 kg/m3.

TLS Screed

Super lightweight aggregate for the preparation of lightweight insulation screed

Our innovative aggregate goes through a range of specific processes that have allowed it to become a market leader for use in thermal and lightweight screeds. This exciting new product offers architects, developers, and builders a great alternative to traditional methods of insulating both ground and upper floors.

When mixed at a specific ratio with cement and water it becomes a lightweight thermal bead screed, with exceptional thermal and acoustic properties and has thermal conductivity values as low as 0.041 W/m.K. TLS offers solutions to reduction in loading with huge advantages in reduction of Dead Loads on intermediate floors with a density of 270 kg/m3.

Thermal Certification

Our TLS aggregate is treated with VOD additives, this enables it to be successfully mixed with cement and water. Sections of this material, TLS has undergone stringent thermal testing by TUV SUD to achieve our thermal certification

Why Use TLS?

Thermal Certification

Our TLS aggregate is treated with VOD additives, this enables it to be successfully mixed with cement and water. Sections of this material, TLS has undergone stringent thermal testing by TUV SUD to achieve our thermal certification

Why Use TLS?

The production and installation of TLS is considerably faster than any other thermal insulation method. This means quicker installation, greater time efficiency, and ultimately considerably lower labour costs.

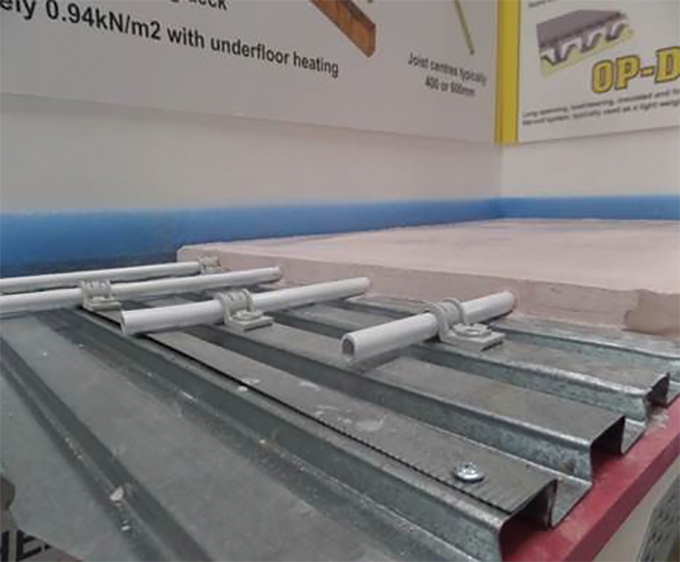

TLS is proven to have considerably greater insulation properties than traditional methods. TLS provides a uniform monolithic insulation slab across the entire floor space. Once on-site, it is easily installed as it is a perfectly homogenous, jointless and flowable material. TLS encapsulates pipe and duct work and enables underfloor heating to reach its full potential.

The volume of required TLS screed for any given project can be calculated before production begins. Only the required volume is produced, therefore dramatically reducing waste from the Installation. This enables TLS to be more Eco-friendly than traditional methods.

TLS is one continuous monolithic layer of thermal material, upon which all forms of screed can be applied. In comparison to other floor insulation options, TLS provides a considerably more even and consistent U Value across the entire floor area.

TLS product is priced solely by total volume. Given that the total required volume for any given project can be calculated before beginning, this means that with TLS there will be no hidden costs or surprises.

TLS has been independently tested with results that evidence a proven and considerable enhancement in underfloor heating efficiency when compared with other commonly used insulation materials. A sound base to secure UFH pipework is critical in avoiding floating pipework which could induce cracks within screeds, and potentially led to non-uniform distribution of heat.

The production and installation of TLS is considerably faster than any other thermal insulation method. This means quicker installation, greater time efficiency, and ultimately considerably lower labour costs.

TLS is proven to have considerably greater insulation properties than traditional methods. TLS provides a uniform monolithic insulation slab across the entire floor space. Once on-site, it is easily installed as it is a perfectly homogenous, jointless and flowable material. TLS encapsulates pipe and duct work and enables underfloor heating to reach its full potential.

The volume of required TLS screed for any given project can be calculated before production begins. Only the required volume is produced, therefore dramatically reducing waste from the Installation. This enables TLS to be more Eco-friendly than traditional methods.

TLS is one continuous monolithic layer of thermal material, upon which all forms of screed can be applied. In comparison to other floor insulation options, TLS provides a considerably more even and consistent U Value across the entire floor area.

TLS product is priced solely by total volume. Given that the total required volume for any given project can be calculated before beginning, this means that with TLS there will be no hidden costs or surprises.

TLS has been independently tested with results that evidence a proven and considerable enhancement in underfloor heating efficiency when compared with other commonly used insulation materials. A sound base to secure UFH pipework is critical in avoiding floating pipework which could induce cracks within screeds, and potentially led to non-uniform distribution of heat.

CERTIFICATIONS

TLS has achieved the Certificate for Factory Production Control (FPC) by CPC (Construction Productions Certification) for the manufacturing process of Expandable Polystyrene Beads (PS5) Intended for use in ready mixed concrete screeds. This revered certification recognises and evidence the proven high standard of Lightherm product manufacturing and Quality processes in accordance with the relevant clauses of EN 16025-1:2013 and EN 13172:2012.

TLS has achieved the Certificate for Factory Production Control (FPC) by CPC (Construction Productions Certification) for the manufacturing process of Expandable Polystyrene Beads (PS5) Intended for use in ready mixed concrete screeds. This revered certification recognises and evidence the proven high standard of Lightherm product manufacturing and Quality processes in accordance with the relevant clauses of EN 16025-1:2013 and EN 13172:2012.

Screed

Stoneyford Traditional

Our Floorscreed is pan mixed and tipper delivered to maintain quality, consistency and reduce balling. We can provide a screed to suit all the application that include retarded & fiber solution.

Quick Drying Screed

Our quick drying screed is designed to accelerate the drying time of which allows faster traffic access onto the screed bed. Our QD screed by its function of water reduction will also reduce the occurrence of drying shrinkage in the screed. Our is suitable for fully bonded, unbonded, floating and heated screeds with or without fibre reinforcement, produce a levelling screed that is capable of receiving floor coverings such as tiles, wood, carpet & vinly.

Stoneyford Gyvlon Liquid Screeds

Gyvlon bring 30 years of screed experience

Gyvlon® Screed in partnership with Stoneyford will produce a full range of fluid screeds, quality requirements. Ready-to-use, they are then Screed delivered by truck to be pumped and poured on site.

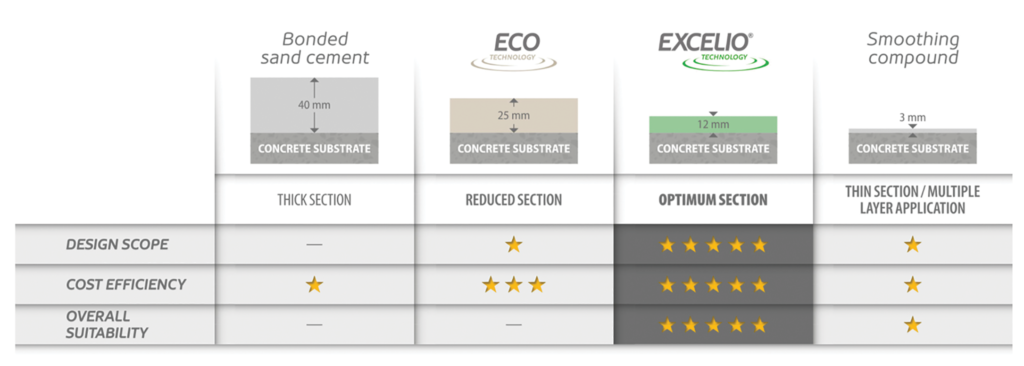

ECO Screed

ECO screed is fully BBA Approved ensuring quality and performance.

Speed up build programme

Screed deadlines are critical, ECO can be installed at up to 200 m? per hour.

Drying times

Drying time for a screed is approximately 1mm per day, up to 40mm. Beyond 40mm, 0.5mm, per day. Underfloor heating, may also be used to reduce the screed drying time. After 48 hours, the building must be properly ventilated

Flexibility of floor coverings.

Flowing screed requires fewer expansion joints than cementitious screeds. Reducing expansion joints preserves the look of the floor finish. Durability of the screed ensures the best possible surface for a final floor finish.

Improving the efficiency of underfloor heating.

As a free flowing and self compacting screed, ECO is versatile for the majority of build types and is compatible with most acoustic and thermal insulations.

Stoneyford Gyvlon Liquid Screeds

Gyvlon bring 30 years of screed experience

Gyvlon® Screed in partnership with Stoneyford will produce a full range of fluid screeds, quality requirements. Ready-to-use, they are then Screed delivered by truck to be pumped and poured on site.

ECO Screed

ECO screed is fully BBA Approved ensuring quality and performance.

Speed up build programme

Screed deadlines are critical, ECO can be installed at up to 200 m? per hour.

Drying times

Drying time for a screed is approximately 1mm per day, up to 40mm. Beyond 40mm, 0.5mm, per day. Underfloor heating, may also be used to reduce the screed drying time. After 48 hours, the building must be properly ventilated

Flexibility of floor coverings.

Flowing screed requires fewer expansion joints than cementitious screeds. Reducing expansion joints preserves the look of the floor finish. Durability of the screed ensures the best possible surface for a final floor finish.

Improving the efficiency of underfloor heating.

As a free flowing and self compacting screed, ECO is versatile for the majority of build types and is compatible with most acoustic and thermal insulations.

ECO Fast Drying Screed

Designed for jobsites with short lead times, Fast Drying screed enables floor coverings to be applied at least twice as fast as our traditional screed. In addition, Our ECO screed brings together all the proven benefits expected from our traditional screed which also includes low-skin option.

Productivity and ease of use

The ECO FD screed (an improved version of eco) exhibits very high productivity rates (200m7/h). It is possible to walk on after 24 hours, and will generally accept trades, foot traffic within 48hrs. Once suitable moisture levels are attained, the screed can be covered without any risk of cracking or curling.

Versatility and freedome of laying tiles or vinyl, etc.

Our FD Screed offers great versatility and is used for all applications: underfloor heating/cooling, thermal & sound insulation, floor levelling… Unlike cement-based screeds, the virtual absence of expansion joints preserves the aesthetics of the floor coverings and allows all the freedom both in terms of tile sizes and layouts (diagonal installation, lack of joints, etc.) or vinyl coverings (hospitals, sports halls, etc.)

Our FD (Faster Drying) technology modifies the internal screed structure to speed up the drying process, drying times are at least twice as fast : it opens the doors for quicker floor covering.

Thermio & Fino Screeds

Thermio Screed for high performance underfloor heating

Thermio screed improves the performance of underfloor heating systems by creating a screed that is specifically designed to complement low temperature heating systems. Thermio screed is the only screed with a BBA guaranteed thermal performance. Greatly improved comfort, the floor emits the heat in a more efficient and homogeneous way thanks to the exceptional thermal emission value of Thermio (up to 30%). Maximising your underfloor heating performance.

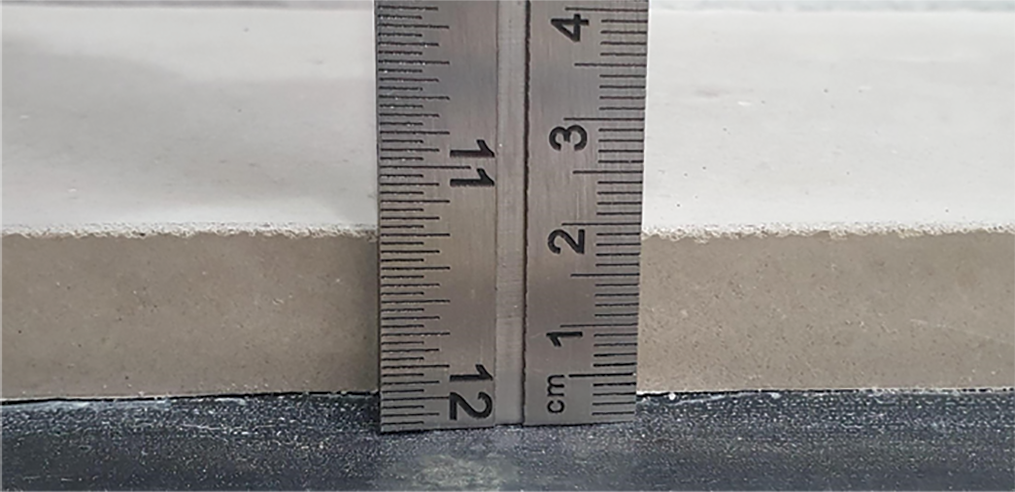

Fino Screed the thin and lightweight solution

Fino technology has been developed to offer a very thin readymix screed solution with minimal thickness of 20mm (unbonded), 25mma (resilient layer) or 30mmb (floating insulation). Thanks to the combination of low thickness and reduced weight, Fino is the ideal flowing screed solution for projects, particularly in renovation, where ceiling heights and/or low floor weights are key.

Thin Section – Up to 60% thickness reduction when unbonded vs. traditional screed

Lightweight – Down to 40 kg/m? when unbonded, 60% lighter compared to traditional

Saving – Readymix solution, no site mixing, no bag storage, ensuring a high productivity

Versatility – Suitable for most floor conditions and all kinds of floor finish

Excelio & XTR Screed

Excelio - Ulta-thin readymix flowing subbase leveller

Excelio offers a unique readymix solution bridging the gap between self-smoothing compounds and bonded screeds. Excelio is the only readymix liquid flowing screed that can be bonded at just 12mm; eliminating the need for site batching multiple mixes, saving time and money.

XTR -Strongest screed for demanding situations

Achieve high strength with no compromise

xTR is a cost-effective and flexible liquid flowing screed which exhibits high mechanical performance (C35-F7)

High strength and low thickness

XTR combines high mechanical performance (C35-F7) with a low section (30mm unbonded) which allows its utilization in building where increased loads are require.

High load floating floor

Ideal on floating screed floors subjected to both high dead and temporary loading,

Achieve high strength with no compromise

xTR is a cost-effective and flexible liquid flowing screed which exhibits high mechanical performance (C35-F7)

High strength and low thickness

XTR combines high mechanical performance (C35-F7) with a low section (30mm unbonded) which allows its utilization in building where increased loads are require.

High load floating floor

Ideal on floating screed floors subjected to both high dead and temporary loading,

Sky, Soundbar & Steeldeck Screed

Sky - High performance screed for high rise solution

Sky has been designed specifically for use where pumped screeds are required above 12 storeys. It is specially formulated to help reduce moisture loss to pump lines and reducethe risk of in line segregation whilst maintaining all the normal features of our screeds.

Soundbar Screed timber frame & acoustic flooring

Soundbar System is a unique, total screeded flooring solution which is the only system of its kind to have achieved Robust Detail, E-FT-4. This provides the developer with the confidence and assurance of achieving a performance standard over and above Part E of the building regulations, two EcoHomes credits if registered with Robust Detail.

The SoundBar System delivers by providing a shallower, high quality, solid floor feel. Designed to improve upon the acoustic performance of a traditional timber floor. Soundbar has all the advantages of anhydrite base screeds, but with a more sophisticated and improved acoustic insulation. It can be used in any kind of situation, but its bespoke features tailor it to a design where the acoustic insulation is the most imporatant feature.

Steeldeck Screed

Steeldeck screed is designed specifically to be used with the Lewis Deck dovetail sheeting. This is for use with either timber, metal web or steel joists in masonry, timber or light weight steel structures. Forming either ground, separating or mezzanine floor constructions and providing a smooth level surface in any kind of building.